RESEARCH

The research directions of Prof. Ryan D. Sochol’s Bioinspired Advanced Manufacturing (BAM) Laboratory all stem from the use of additive manufacturing or “3D printing” to advance biomedical fields. Prior to becoming an Assistant Professor, a large portion of Dr. Sochol’s research centered on taking advantage of the scaling-induced benefits of micro/nanotechnologies for applications such as point-of-care medical diagnostics. These efforts, however, also revealed the critical limitations of traditional micro/nanoscale manufacturing techniques, not only in terms of the time-, cost-, and labor-intensive protocols, but also the inherent geometric (“2.5D”) constraints. Thus, the BAM Lab focuses on pioneering alternative micro/nanofabrication strategies based instead on state-of-the-art additive manufacturing technologies, with a focus on applications that objectively demand its use—i.e., cases requiring device architectures and/or functionalities that would be difficult or infeasible to achieve via conventional manufacturing methods.

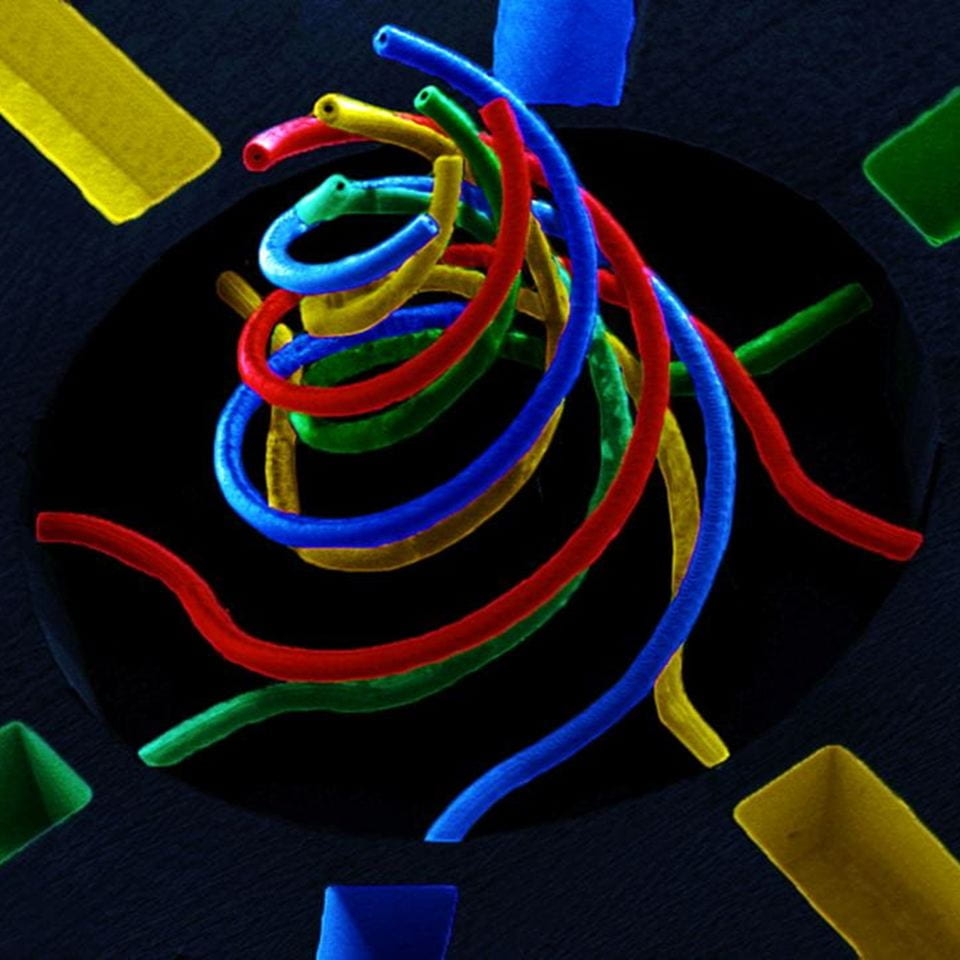

3D Microfluidic Technologies via Direct Laser Writing

“Direct Laser Writing (DLW)” is a two-photon (or multi-photon) polymerization technique that entails rapidly scanning a tightly focused laser to crosslink (i.e., solidify) a photoreactive material at designed locations to ultimately produce 3D objects with feature resolutions down to the 100 nanometer range. The key challenge in employing DLW for microfluidic applications is that the high resolution has rendered it poorly suited for printing the macro-to-micro fluidic interfaces—e.g., the inlet and outlet ports required for delivering/retrieving fluids. To overcome this barrier, our group has invented “in situ DLW (isDLW)” and “ex situ DLW (esDLW)” strategies for printing 3D microfluidic technologies with micron-to-submicron-scale feature resolution.

Highlighted Publications

- Sunandita Sarker, Adira Colton, Ziteng Wen, Xin Xu, Metecan Erdi, Anthony Jones, Peter Kofinas, Eleonora Tubaldi, Piotr Walczak, Miroslaw Janowski, Yajie Liang, and Ryan D. Sochol*, “3D-Printed Microinjection Needle Arrays via a Hybrid DLP-Direct Laser Writing Strategy,” Advanced Materials Technologies, Vol. 8, Issue 5, pp. 2201641, 2023. (*Rising Star* Article; Featured on the Inside Front Cover)

- Abdullah T. Alsharhan, Ruben Acevedo, Roseanne Warren, and Ryan D. Sochol, “3D Microfluidics via Cyclic Olefin Polymer-Based In Situ Direct Laser Writing,” Lab on a Chip, Vol. 19, 2019. (Featured on the Front Cover)

- Andrew C. Lamont, Abdullah T. Alsharhan, and Ryan D. Sochol, “Geometric Determinants of In-Situ Direct Laser Writing,” Scientific Reports, Nature Publishing Group, Vol. 9, pp. 394, 2019.

Highlighted Presentations

3D Printed Soft Robots with Integrated Fluidic Circuitry

Over the past decade, “soft robots”—systems composed of compliant materials that are typically actuated via fluidic means (e.g., hydraulics and/or pneumatics)—have garnered significant interest as the inherent adaptability and safety for human-robot interactions has opened the door to new forms of rehabilitation and medical devices (e.g., soft robotic sleeves for pumping ailing hearts). Yet this emergence of the soft robotics field has also presented new challenges associated with controlling the underlying fluidics of such systems—challenges our group has worked to address by means of additive manufacturing.

“PolyJet 3D Printing” is an inkjet-based process by which multiple photoreactive materials (and a sacrificial support material) are dispensed in parallel to produce multi-material 3D objects in a line-by-line, layer-by-layer manner. We introduced a strategy for additively manufacturing fully assembled soft robots—including all of the soft actuators, integrated fluidic circuitry, and body features—autonomously in a single step via PolyJet 3D printing. Not only is the paper “open access”, but all of the electronic design files are available through GitHub so that anyone can readily download, modify on demand, and/or reproduce (i.e., 3D print on site or via a commercial service) these capabilities. We have also employed our isDLW and esDLW approaches for manufacturing microfluidic circuitry and integrating these components with soft microrobotic actuators with a focus on medical/surgical robotics applications.

Highlighted Publications

- Joshua D. Hubbard†, Ruben Acevedo†, Kristen M. Edwards, Abdullah T. Alsharhan, Ziteng Wen, Jennifer Landry, Kejin Wang, Saul Schaffer, and Ryan D. Sochol, “Fully 3D-Printed Soft Robots with Integrated Fluidic Circuitry,” Science Advances, 2021. (Featured on the Front Cover; † = Equal Contribution)

- Abdullah T. Alsharhan, Olivia Young, Xin Xu, Anthony J. Stair, and Ryan D. Sochol, “Integrated 3D Printed Microfluidic Circuitry and Soft Microrobotic Actuators via In Situ Direct Laser Writing,” Journal of Micromechanics and Microengineering, Vol. 31, Issue 4, pp. 044001, 2021. (*JMM “Early Career Award”* Article; Invited Manuscript for the *JMM “Emerging Leaders”* Special Issue)

Highlighted Presentations

Multi-Material Direct Laser Writing

The ability to manufacture geometrically complex, yet functionally advantageous microsystems comprising multiple fully integrated materials—e.g., corresponding to distinct optical, biological, chemical, electrical, and/or mechanical properties—holds promise for catalyzing new technologies in optics, photonics, biomedical, and microelectronics fields. Historically, however, DLW-printed microsystems have near-universally included only one material due to the limits of conventional multi-material DLW protocols. To address this barrier, we introduced “microfluidic multi-material DLW” .

Highlighted Publications

- Andrew C. Lamont, Michael A. Restaino, Matthew J. Kim, and Ryan D. Sochol, “A Facile Multi-Material Direct Laser Writing Strategy,” Lab on a Chip, Vol. 19, Issue 14, pp. 2340-2345, 2019. (Selected as a “Hot Article”; Featured on the Inside Front Cover)

- Ruben Acevedo, Michael A. Restaino, Dongyue Yu, Sharon Flank, Stephen W. Hoag, and Ryan D. Sochol, “3D Nanoprinted Liquid-Core-Shell Microparticles,” Journal of Microelectromechanical Systems, Vol. 29, Issue 5, pp. 924-929, 2020.